This article introduces the manufacturing situation and great suppliers of Abrasive Belt.

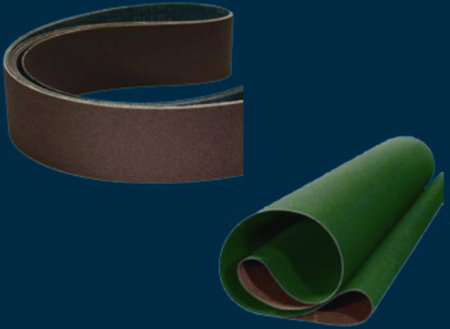

In recent years, the conventional abrasive belt occupies a large proportion in the global consumption of abrasive products, but with the emergence of a large number of new materials and the demand for the specific occasions, the use of high quality abrasive belt has increased year by year. At present, the international has developed a large number of emerging abrasive belt, such as ceramic corundum abrasive belt, diamond abrasive belt, CBN abrasive belt and so on. They generally are classified into three categories: fine abrasive belt, heavy duty abrasive belt and other special types of abrasive belt.

Heap abrasive sanding belt, multilayer abrasive grain sanding belt, non-woven matrix abrasive belt, diamond and CBN abrasive sanding belt are fine abrasive belts. In general, fine abrasive belt refers to using fine-grained abrasive made of single layer or multilayer abrasive belt, usually for precision grinding, grinding and polishing on the surface of the materials.

The use of heavy duty abrasive belt in Europe, America and Japan and other developed countries has formed scale. Early it is mainly used in automotive parts and aerospace engineering with super alloys and titanium alloys such as high efficiency grinding. And late in the metallurgical, chemical, electric power industries, it gradually promotes the use of the application. Thanks to the application of zircon fused alumina heavy duty abrasive belt invented by Norton Company in the United States, whose has high removal rate and long service life. In 1983, the patent SG and TG abrasive as the representive of Norton Company, has brought a powerful new technology revolution in the abrasive belt grinding field. Followed by 3M of United States, VSM of Germany and Noritake of Japan and other companies also have developed new type ceramic corundum abrasives sanding belt.

The third coated abrasive belt is a kind of special abrasive belt that is difficult to machine, also known as super coating abrasive belt. It is coated the third layer – a kind of thin layer material that has a special usage on the basis of the prime coat and composite adhesive, whose chemical composition is usually metal salts formed from halogens element or sulfur element. The purpose is to reduce the grinding temperature, decrease the adhesion and increase the removal rate of the materials. Using SK840X third coated super abrasive belt grinding aeroengine TIA14V alloy turbine blade of Germany VSM Company not only effectively avoid the burn of workpieces, but also realize the efficient heavy grinding of titanium alloy blade.

In the field of wood processing, the antistatic technology of abrasive belt views reducing abrasive belt congestion and preventing burns as the main goal, and also has a fast development in recent years. In 2005, South Korea once launched super wide composite base PC340 antistatic abrasive belt, which could reduce the electrostatic accumulation on the surface of the medium sand belt grinding process through the processing of polyester fiber. It is especially suitable for processing stearic plastic, particle board, plywood, etc.

In order to prolong the service life of abrasive belt and further expand the scope of the processing, foreign research institutions improve the performance of abrasive and at the same time, increase the third layer, optimize sand- planting technology, and finally make the Combi abrasive belt. It uses the supportive abrasive to improve the bond strength of the main abrasive grain on the substrate, which not only has the characteristics of the third layer abrasive belt, but also can further improve the depth of grinding and increase the removal rate of the materials.

In addition, it has also appeared mixed abrasive sanding belt, mixed particle size abrasive belt, density clearance abrasive belt, mesh abrasive belt, cubic boron nitride abrasive belt and abrasive rope and other new forms in the development process of abrasive belts.

If you would like to learn more about abrasive belt and other abrasives, please feel free to visit iAbrasive.com-a B2B web portal located in Zhengzhou, China, which is devoted to the development of abrasives foreign trade B2B platform. We offer many chances for buyers and suppliers for better deals. For example, some abrasive belts suppliers are very popular and gold members at iAbrasive and if you are interested, you can click the links: Zhengzhou Jiasheng Abrasives Co, LTD., Shanghai Fermi Abrasives Co., Ltd., Dongguan Houjie FENGRUI Abrasives Factory, CIPIE(Henan)Import and Export Trade Co.,LTD and AVIC Tianshui New & High Abrasives Co., Ltd.They can offer high quality abrasive belts for you.

At iAbrasive, our mission is to create a good platform for chatting and interaction, expanding buyers and suppliers interaction space and interactive way, and bring our customers more business opportunities and exceptional value. Click on the link www.iabrasive.com to get more business opportunities, or click on the "register" link if you are interested in becoming a member of iAbrasive.