The characteristics of heavy-duty grinding wheel are high working speed, huge grinding force, and high grinding efficiency, which has decided the high demand for the grinding wheel's mechanical strength that depends on the grinding wheel's structure.

Abrasive

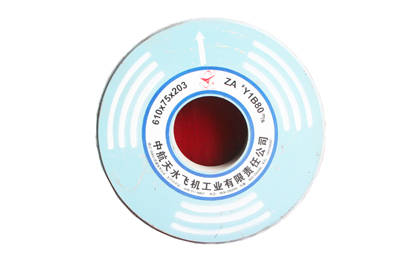

The characteristics of heavy-duty grinding wheel are high working speed, huge grinding force, and high grinding efficiency, which has decided the high demand for the grinding wheel's mechanical strength that depends on the grinding wheel's structure. The specific value of the three influencing factors--abrasive grains, bonding agents, and pores, and their distribution decide a grinding wheel's structure. To produce a grinding wheel of dense structure, the briquetting pressure should be increased, which is decided by the fragility and intensity of abrasive. The major abrasive used for heavy-duty grinding wheels include the following types:

Heavy-duty grinding wheel at first used brown fused alumina as abrasive, which has a high toughness and high crush resistance. Brown fused alumina is generally employed to produce low-duty grinding wheels and medium-duty grinding wheels.

2. Sintered Alumina

Sintered alumina can be subdivided into bauxite sintered alumina, aluminum oxide sintered alumina, and sintered zirconia alumina, etc. These sintered aluminum oxide abrasive are proper for producing heavy-duty grinding wheels.

3. Zirconia Alumina

Zirconia alumina is a kind of high efficiency grinding abrasive that is universally adopted in heavy-duty grinding wheel manufacturing both in China and abroad. Usually the ZrO2 content in aluminum oxide is required to reach 25% to 40%. The crystal size is 20 micron, at most no more than 40 micron. Zirconia alumina whose ZrO2 content is 25% is often used to produce heavy-duty grinding wheels.

4. Grit Size

To improve grinding efficiency, heavy-duty grinding wheels mostly adopt coarse grains. Currently, the most frequently used grit sizes are 6#, 8#, 14#, 16#, 20#, 24#, 30#, 36#, etc.

Bonding Agents

Bonding agent is a key constituent of grinding wheels. The function of bonding agent is to bond together abrasive grains to form a grinding wheel that can grind. So far, the main bonding agent used in heavy-duty grinding wheels has been phenolic resin, which comes in a lot of categories. Users are suggested to choose phenolic resin that has a good thermal stability and has a strong binding force of abrasive grains. Its mechanical behavior, namely, tensile strength, hardness, flexural strength, should also be high. Phenolic resin is divided into liquid and powdery. The latter is the choice for almost all the heavy-duty grinding wheel producers worldwide. Although powdery phenolic resin heavy-duty grinding wheels have a good elasticity, resin carbonization under high temperature cannot be solved. Abrasive products produced by inorganic polymer bonding agents can solve the series of problems and further improve the performance of abrasive products.

Plugging Compound

Since the intensity of heavy-duty grinding wheel has been improved, simply depending on the high intensity of abrasive and bonding agents is not adequate. To enhance the grinding wheel's intensity and its performance, certain plugging compound should be added. Heavy-duty grinding wheels need a large amount of plugging compound, including metal sulfide powder, such as cryolite, calcium fluoride, calcium carbonate, pyrite, lead sulfide, etc. In addition, mineral short fibers, such as glass fiber, slag wool, ceramic fiber, and asbestos, are also included. Usually no plugging compound is needed when using inorganic polymer bonding agents to produce abrasive products.

Author: Liwei Chu

Copyright: iAbrasive.com--Abrasives & Diamond Tools Market