Grinding wheel blockage is one of them, which is caused by a lot of reasons. Today we are going to learn about the effects of abrasive grain size on grinding wheel blockage.

There will be some problems in the process of using Grinding wheels. Especially the longer you use the more questions there will be. Grinding wheel blockage is one of them, which is caused by a lot of reasons, such as, abrasives, linear velocity and hardness, etc. Today we are going to learn about the effects of abrasive grain size on grinding wheel blockage:

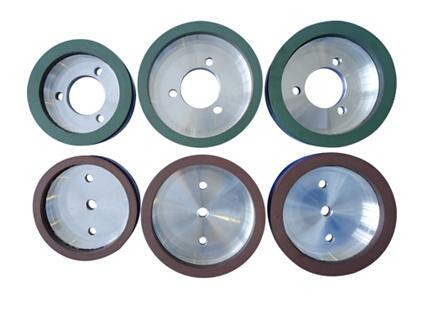

Different grinding wheels all have their own different grinding grain shape and density, as well as the size, such as, diamond grinding wheel, etc. Thus, grinding wheel blockage has different reasons, but generally speaking, fine and dense grits is easy to cause blockage, because fine-grained grinding wheels have high density and small gap between abrasive grain, and the pores of grinding wheel are also small. If grinding wheels have more abrasive grains, the grinding and cutting will be more, and then the chip is relatively small in machining products. The porosity and void will be soon to fill by abrasive dust and powder when grinding, and coupled with less porosity, the heat generated by grinding wheel and workpieces is difficult to spread out, which accelerates the increase of the grinding heat that is easy to melt some powder, so the powder will be bonded on grinding wheel clearance easily.

And coarse-grain grinding wheels have bigger abrasive grains and cutting edge. Their cutting quantity is big, and bigger cutting block is not easy to plug the gap between the abrasive grain and porosity. There are wide gap between abrasive grains, and also can not be filled quickly. What’s more, the porosity is not easy to jam, so the cooling system is in good condition. As a result, the coarse-grain grinding wheels may be slower than that of fine-grain grinding wheels in the beginning, but in the later stage, namely, the coarse-grain grinding wheels are more likely to cause blockage phenomenon rather than fine-grain grinding wheels. That is because at that point, the fine-grain grinding wheels have better sharpness than coarse-grain grinding wheels, so coarse-grain grinding wheels blockage is more serious.