Element Six the pioneer in synthetic diamond supermaterials and member of the De Beers Group, has developed a new diamond optics range, called Diamond PureOptics.

Element Six the pioneer in synthetic diamond supermaterials and member of the De Beers Group, has developed a new diamond optics range, called Diamond PureOptics. Drawing inspiration from the anti-reflective structure of a moth's eye, this all-diamond solution offers improved reliability and even higher power density levels for high power CO2 laser systems.

The developer says these diamond optics are suited for CO2 laser and EUV applications: “The all-diamond meta-surfaces design exhibits a significantly higher laser-induced damage threshold, by a factor of 10, than anti-reflective coated windows, with equivalent reflectance below 0.5% and transmission above 99%.”

Due to a combination of its significant thermal, mechanical and optical properties, diamond grown by chemical vapor deposition (CVD) has become the material of choice for windows for high power, multi-kilowatt CO2 laser systems. Its wide transmission window from the UV through to the RF part of the electromagnetic spectrum, combined with the highest hardness and thermal conductivity of any material makes diamond an in-demand material for robust optics.

Now, as demand grows for faster through-put, and new applications emerge such as extreme ultraviolet lithography, which use CO2 lasers to generate sub-10nm radiation, Element Six says new advanced solutions are needed to produce more robust optics. The PureOptics launch release states, “To meet the associated application requirements, Element Six has pushed diamond synthesis and processing capabilities to new heights.”

Diamond optical windows typically include an anti-reflective thin film coating to minimize reflection losses at each surface, associated with the change in refractive index of diamond to air, maximizing laser output power. However, these coatings have mechanical and thermal properties that can be 1,000 times inferior to those of the intrinsic diamond, leading to increased thermal and mechanical failures as optical power densities increase.

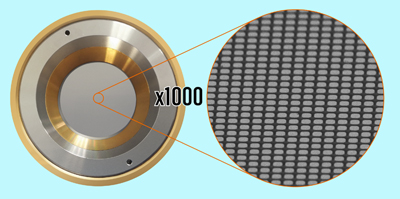

’Moth’s eye’ design

By mimicking the structure of a moth's eye, Element Six has replaced these thin films with a diamond-structured surface designed to reduce reflection losses, shifting the reliance of the optics solely onto the intrinsic properties of diamond. Element Six states, “Diamond PureOptics with meta-surfaces offers improved reliability and allows even higher power density levels for high power CO2 laser systems, making them ideally suited for EUV applications.

Bruce Bolliger, head of sales and marketing at Element Six Technologies, said, “With the industry trending to even more powerful CO2laser sources and the high costs associated with system downtime, the need for more durable and reliable anti-reflective laser windows is critical. Creating an all-diamond solution increases durability and enables higher power by eliminating more vulnerable antireflection thin films, which are often the first to fail in extremely high power density applications such as EUV lithography."

Element Six adds that research comparing the performance of conventional AR coated windows with its new diamond windows “clearly demonstrates the superiority of MS in regards to reliability and thermal management. While in bench marked tests AR coated windows demonstrated a laser induced damage threshold at ~0.25 MW/cm2, the same laser was unable to damage the MS window at all, even at power densities 10 times higher. Additionally, exchanging AR coatings with MS decreased overall window absorption, helping to keep window operating temperatures low and minimize thermally induced beam distortion.”