As a global technology leader in advanced silicon carbide materials, Dow Corning today established a higher industry standard for silicon carbide (SiC) crystal quality by introducing a product grading structure.

Dow Corning today established a higher industry standard for silicon carbide (SiC) crystal quality by introducing a product grading structure that specifies ground-breaking new tolerances on killer device defects, such as micropipe dislocations (MPD), threading screw dislocations (TSD) and basal plane dislocations (BPD). This groundbreaking new grading structure aims to optimize the range, performance and cost of next-generation power electronic device designs fabricated on Dow Corning's high-quality Prime Grade portfolio of 100mm SiC wafers, which the company now offers in three new tiers of manufacturing-quality substrates labeled Prime Standard, Prime Select and Prime Ultra.

"As a global technology leader in advanced silicon carbide materials, Dow Corning recognizes that wide-bandgap semiconductor technology must deliver much more than high quality alone – it must deliver exceptional overall value," said Gregg Zank, chief technology officer, Dow Corning. "Another Dow Corning industry first, our new SiC wafer grading structure meets this need head on. It is the direct result of our close collaboration with the globe's leading power electronics device manufacturers, and aims to help give them what they need to quickly achieve their evolving design goals at an optimal price point."

Each successive Prime Grade wafer tier under Dow Corning's new product grading structure offers tighter tolerances for defect density and other critical performance properties that allow customers to precisely While many SiC substrate manufacturers promise low micropipe densities, Dow Corning is the first to specify low tolerances of other killer defects, such as TSD and BPD. Such defects reduce device yields, and inhibit the cost-efficient manufacture of large-area, next-generation power electronic devices with higher current ratings.

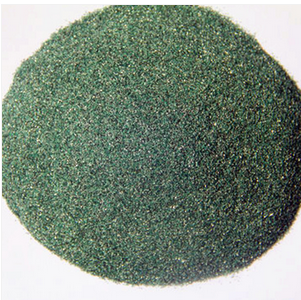

See more silicon carbide products at: http://www.iabrasive.com/products/green-silicon-carbide.