Do you know different classification methods of sanding discs? This article will tell you in detail.

Sanding Discs: First of all, put sanding disc roll and two-side glue on the punching machine and then cut it with a special circular mould. Because its shape is a circle, it is called sanding disc whose essence is the sandpaper. According to the size, plying-up, sand surface and other aspects, sanding disc is divided into multiple species.

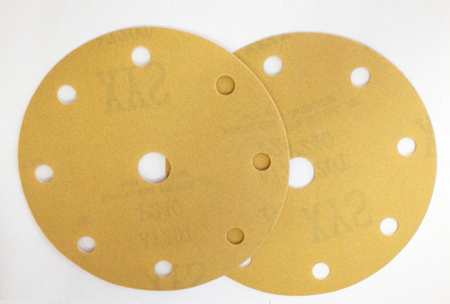

Different classification methods of sanding disc: According to different plying-up, it is divided into adhesive sanding disc and hook & loop sanding disc, with hole or no hole. When the perforated sanding disc is grinding some objects, the scraps can drop from the hole, which improves grinding efficiency; According to the size, it can be divided into 4 inches, 5 inches and 6 inches; According to the sand surface, it can be divided into white sand surface, red sand surface, yellow sand surface, blue sand surface, green sand surface, etc.

In numerous sanding discs, some of them can be divided into dry and wet sandpaper. So what's the difference between dry and wet sandpaper?

Wet sandpaper is small and its grinding chippings is also small. If we use sandpaper and water together, the chippings can flow out by following the water. So, it is better to use with water. And it is very convenient to use dry sandpaper. Because of its larger gap between sand, the chippings will fall off in the process of grinding, so it is better not to use with water.

Sandpaper is used to grind the surface of metal and wood, which can make their surface bright and clean. According to different grinding material, it can be divided into emery paper, artificial emery paper, glass paper, etc. And wood sandpaper is used for polishing wood and bamboo surface. And waterproof sandpaper is used in the water or oil to polish the surface of metal or nonmetal workpieces. There is still a kind of adhesive sandpaper that needs to be glued or flocking processing on the back of corresponding sandpaper or sandcloth, and then cut into the shape of a circle or others after stamping, which is widely used in the surface treatment of automobiles, furniture, metal products, electronic circuit boards and other products.