The success of using diamond tools in the aerospace industry is mainly due to the properties this material possesses, leading to a longer tool life and improved cutting speeds compared to conventional materials.

Nickel-based super alloys and composites are examples of such materials. However, they are difficult to cut and require specific machining techniques. As a result, diamond is used for applications in which conventional tools cannot be used to reach the final objective of the manufacturing process.

Using Diamond for Longer Tool Life and Improved Cutting Speeds

The success of using diamond tools in the aerospace industry is mainly due to the properties this material possesses, leading to a longer tool life and improved cutting speeds compared to conventional materials.

Diamond has the highest value on the Mohs scale of mineral hardness. This scale allows the classification of the resistance to scratching of a material and has a range comprised between 1 (softest) and 10 (hardest).

Diamond tools can be created using different types of the material, depending on the specific application and product requirements. Diamonds can be categorised as either natural or synthetic. Synthetic diamond materials can be classified in different classes: grains and powders, PCD (Polycrystalline Diamond) and CVD (Chemical Vapour Deposition).

Synthetic Diamond Grains

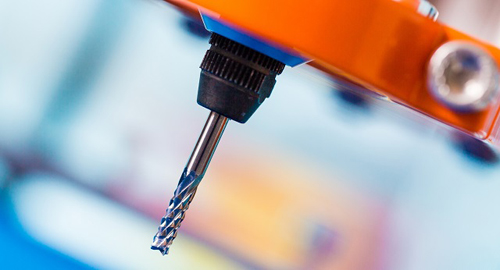

Synthetic diamond grains (grits) and powders are used as abrasives, bonding them to the surface of a tool. This can be achieved in different ways depending on the required process characteristics, such as tool rotational velocity.

Diamond particles can be deposited on the tool surface either using an electroplating technique, using a nickel solution or by sintering them in a tungsten based matrix. Another technique known as braze bonding, works by brazing the diamond particles to the tool metal surface.

Each of these bonding methods have associated benefits and drawbacks related to the tool manufacturing time and the capabilities of the binder in retaining the diamond particles, depending on the final operational characteristics.

PCD (Polycrystalline Diamond) Tools

In PCD tools (or inserts), segments of diamond are bonded, typically using brazing, to a carbide substrate. PCD elements are produced by sintering micron-sized synthetic diamond powders to bond particles together in a process characterized by high temperatures and pressures.

This material is manufactured using cemented carbide baking which provides the metal source necessary, typically cobalt, in order to carry out the sintering process. During the production process the metal from the carbide substrate penetrates between the diamond grains, allowing them to be bonded together.

The metallic content of PCD provides the material with electrical conductivity properties, allowing the use of machining process such wire EDM (Electrical Discharge Machining) in order to cut diamond elements.

CVD Diamond Tools

Another type of synthetic diamond is produced by using a technique known as chemical vapour deposition. CVD diamond is deposited in thin layers on the surface of a tool in a tightly controlled growth condition process.

One of the main advantages in using this kind of synthetic diamond is the possibility to obtain addition geometries and cutting edges, using a material characterized by highly predictable properties.