Using the correct grinding wheel dresser, not only can reduce the dressing time of grinding wheel, but also improve the efficiency, accuracy and prolong the service life of grinding wheel.

In the era of globalization and the competitive environment, to reduce the cost is the most important link; Using the correct grinding wheel dresser, not only can reduce the dressing time of grinding wheel, but also improve the efficiency, accuracy and prolong the service life of grinding wheel.

Now the commonly used dressing methods of many industries for grinding wheel are: aluminum oxide sharping sticks, diamond knife, molybdenum, copper, or mild steel, etc. The free abrasive rolling cross dressing which does not destroy the whole structure of grinding wheel, can effectively prolong the service life of grinding wheel.

Most grinding and processing industries at home and abroad in the past use traditional dressing methods of grinding wheel, such as mild steel, copper, molybdenum metal or other tools, which are both time-consuming and destruct the whole structure. In addition, they can reduce the service life of grinding wheel, and are not easy to obtain the best dressing precision of grinding wheel in large size, wide edge grinding wheel, very thin and fine granularity.

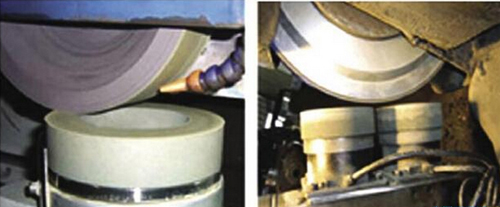

A new generation of Dia&CBN diamond /boron nitride grinding wheel dresser, uses the way of free abrasive dressing, which is quicker about 20 times compared with the general dressing; The dresser is used for mirror grinding of cylindrical grinding machine and high precision mould, and the dressing accuracy, roundness and flatness are within 0.1μm. It has high efficiency and simple operation, mostly effective to extend the service life of grinding wheel, which is necessary tools for precision and mirror grinding.