Discover how silicon carbide abrasives are used across grinding, polishing, and semiconductor industries. Explore global demand trends by country and application.

Silicon carbide (SiC) has long been a cornerstone in the abrasives industry. Known for its exceptional hardness, thermal conductivity, and chemical stability, SiC abrasives are widely used in grinding, cutting, surface preparation, and precision polishing. But beyond its technical strengths, global demand for silicon carbide abrasives is evolving — driven by manufacturing trends, renewable energy, and the rise of high-tech applications.

In this article, we’ll explore the key applications of silicon carbide abrasives and provide a breakdown of global market demand by region and industry.

1. What Makes Silicon Carbide Unique?

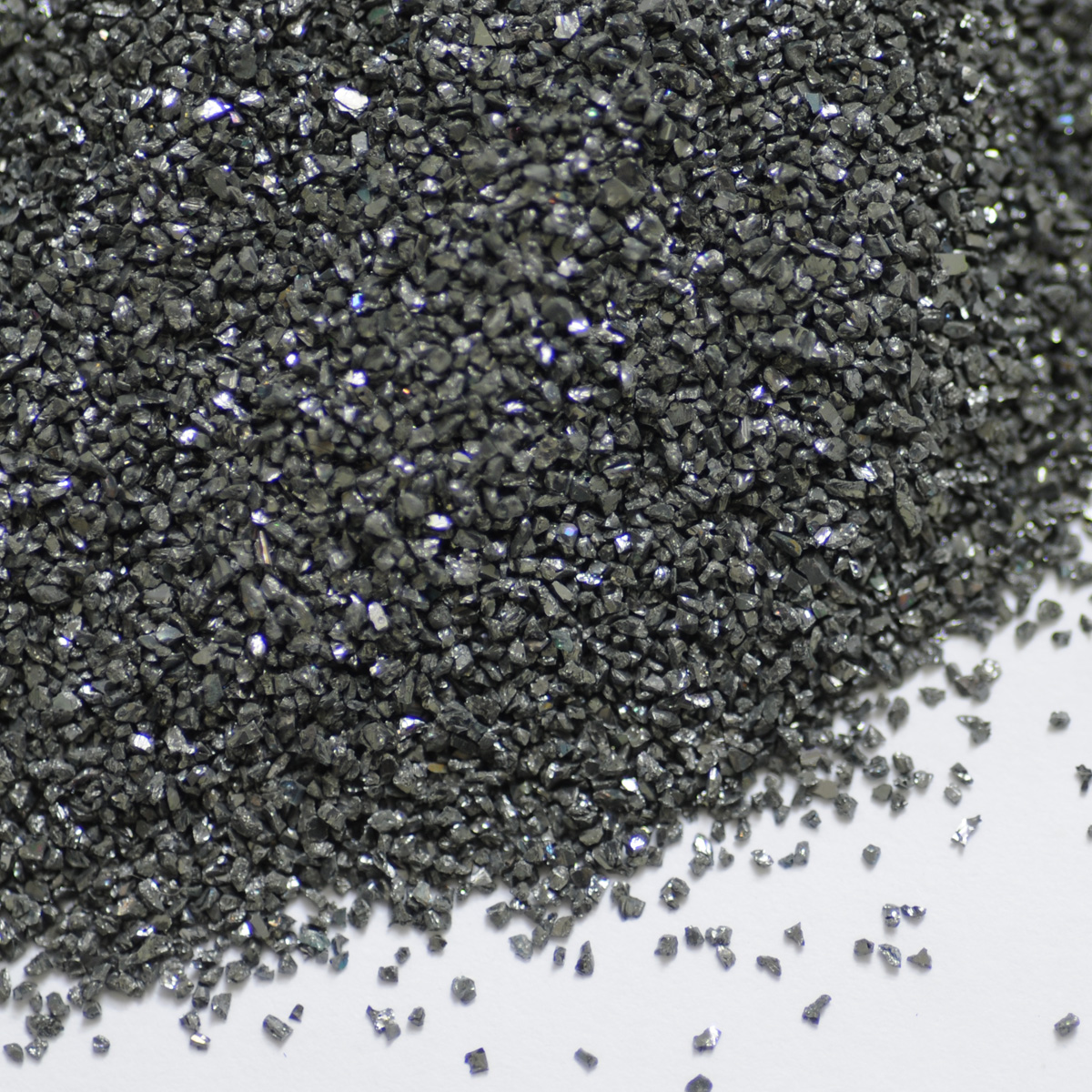

Silicon carbide abrasives are made through high-temperature smelting of silica sand and petroleum coke. The resulting crystals — either green or black — are extremely hard (Mohs hardness 9.2–9.3), thermally stable, and chemically resistant. This makes SiC ideal for materials that are difficult to machine, such as ceramics, glass, hard alloys, and even silicon wafers.

2. Main Applications of Silicon Carbide Abrasives

Bonded Abrasives (Grinding Wheels, Cutting Discs)

Grain Size: F12 to F220 (FEPA standard)

Uses: Grinding hard metals, cast iron, stainless steel.

Key Industries: Foundries, steel mills, machinery manufacturing.

Coated Abrasives (Sanding Belts, Papers, Flap Discs)

Grain Size: P24 to P2500

Uses: Woodworking, metal polishing, paint removal, glass finishing.

Key Industries: Automotive, furniture, consumer goods.

Blasting Media

Grain Size: F16 to F80

Uses: Surface cleaning, derusting, etching, glass frosting.

Key Markets: Middle East, Southeast Asia, shipyards, metal structures.

Micron and Sub-Micron Powders

Grain Size: F240 to F1200, W7 to W1

Uses: Precision polishing, silicon wafer cutting, sapphire processing.

Key Industries: Semiconductors, photovoltaics, LED.

Refractory Materials

Form: Lumps and large grains

Uses: Kiln linings, blast furnace nozzles, high-temp bricks.

Key Industries: Steelmaking, cement, glass, petrochemicals.

Advanced Ceramics & Composites

Uses: Ceramic armor, seals, automotive brake discs.

Key Regions: Germany, Japan, U.S.

3. Global Demand Distribution by Region

China

The world’s largest producer and consumer of SiC abrasives.

Strong demand across grinding, refractory, and solar sectors.

Home to many OEM abrasive tool manufacturers.

Growing demand for micron powder in photovoltaics and LED.

India

Rapid industrialization fuels demand for cutting and grinding tools.

High-volume consumption in metalworking, infrastructure, and automotive.

Germany & EU

High-quality demand for precision SiC abrasives.

Used in automotive polishing, aerospace grinding, ceramics.

United States

Mature market with stable demand in semiconductors, defense, and coatings.

Key user of green SiC for glass and electronics polishing.

Japan & South Korea

Heavy focus on ultra-fine SiC powders for semiconductors and displays.

Japan is a leader in precision coated abrasives.

Brazil & Turkey

Growing needs for SiC in construction, mining, and metal casting.

4. Market Trends & Opportunities

|

Trend |

Details |

|

Rising Micro Powder Demand |

Driven by solar panel production and Si wafer cutting |

|

High-End Coated Abrasives |

Strong demand in automotive, aerospace, electronics |

|

Eco-Friendly Surface Processing |

SiC preferred for dust-free and recyclable media blasting |

|

New Energy Vehicles (NEV) |

SiC ceramics used in power electronics and EV braking systems |

Conclusion

Silicon carbide abrasives are no longer just for traditional grinding. They’re essential in precision manufacturing, sustainable energy, and next-gen electronics. For buyers, staying ahead means understanding the right grain size, application fit, and regional sourcing strategy.

At DOMILL, we’ve been delivering high-purity, custom-graded silicon carbide abrasive grains to global manufacturers for over 30 years. Whether you need F-grit for grinding wheels or sub-micron powders for wafer slicing, our team can help you source with confidence.

Contact us today for free samples or technical consultation.